Finding yourself with a stuck allen screw or bolt but no wrench or key can be frustrating, especially when you’re in the middle of a project. Sometimes, even with the right size tool, the bolt may feel loose and fail to grip properly. While an allen screw has a tapered top and an allen bolt has a cylindrical top, both can still be removed using tools and supplies you probably have at home. There are multiple ways to remove them efficiently, and knowing the best tips will help you get that pesky screw out while minimizing damage to your workpiece. Whether you’re a DIY enthusiast, mechanic, or repair technician, these solutions will come in handy when you don’t have the proper tool.

Instead of breaking a sweat, consider some alternative tools that work just as well. A hex wrenches set or a Torx key set is a good idea to keep on hand, especially if you often work on fixing bikes, machines, or assembling furniture. However, if you don’t have one nearby, try investing in a suitable key set for the long run. There are also methods to use common tools to get the job done. This guide will help you realise how to tackle an unmovable bolt without causing injury or leaving your tools damaged. Whether you’re working on automotive parts, appliances, or anything else, these tips will ensure you always have a solution at hand.

How to Remove an Allen Bolt Without an Allen Key

If you don’t have an Allen key, you can still remove an Allen bolt using common household tools. A Torx screwdriver with a slightly larger bit can provide a strong grip inside the bolt head, making it easier to turn. A flathead screwdriver pressed firmly into one of the hex socket corners can also work, especially when combined with a rubber band for extra traction. If the bolt has a raised head, locking pliers or a small adjustable wrench can grip it securely for removal. For stubborn bolts, applying penetrating oil, using a socket wrench, or gently tapping a screwdriver with a hammer can help loosen it. These quick and effective methods ensure you can remove an Allen bolt without damaging your workpiece.

Use a Torx Screwdriver

One of the easiest ways to remove a stripped Allen-head screw is by using a Torx wrench. Its 6-pointed star-shaped bit provides a stronger grip inside the hole of the bolt, making it easier to turn counterclockwise. If you have a tool kit at home, you might already own a Torx screwdriver or wrench. Just choose a bit that’s slightly larger than the screw head, then push it in firmly before attempting to turn. If the shape is the right fit, this method works well. If you don’t have one, you can buy a set from a local hardware store or online to keep for future repairs. It’s always a good idea to try different sizes to see which one fits best.

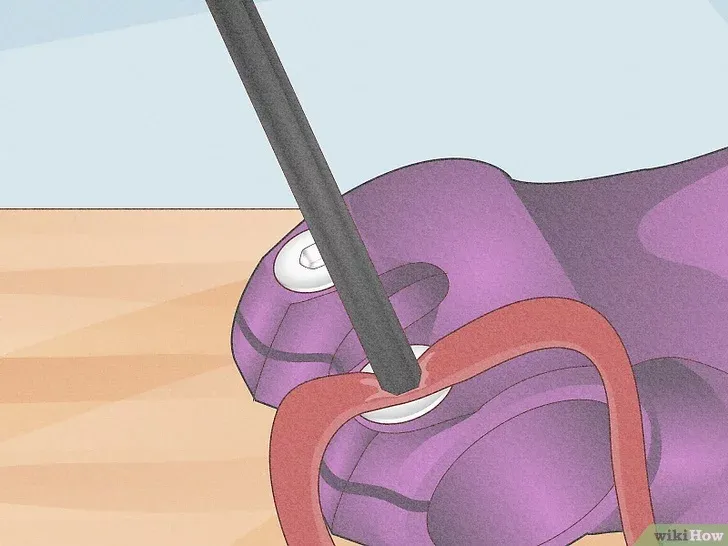

Use a Flathead Screwdriver

If you don’t have an Allen wrench, a flathead screwdriver can be a great substitute. Just insert it into one of the corners of the hex socket, making sure it fits firmly. To enhance grip and prevent slipping, place a rubber band or a disposable glove over the tip of the screwdriver.** This trick works best when dealing with slightly loose bolts. A wide rubber band can completely cover the hole of the bolt or screw, adding a layer of traction for easier unscrewing. If you still struggle, push the screwdriver down hard and turn gently while applying steady force. You can also try using a wrench to hold the screwdriver in place for extra leverage. This method is simple and effective, making it enough to remove most Allen bolts even in a pinch.

Try a Small Adjustable Wrench

If the Allen bolt has a slightly raised head and is accessible, using a small adjustable wrench is a great method to remove it. Carefully position the wrench around the sides of the bolt and apply steady pressure to loosen it. This works well when the bolt is not completely flush with the surface. Make sure to grip it firmly and turn it slowly to avoid damage.

Use Locking Pliers for a Stronger Grip

Pliers, especially locking pliers, are an effective tool for removing a stripped or damaged Allen bolt. The locking pliers can tightly grip the bolt’s head, making it easier to turn counterclockwise. While regular pliers may also work, they require constant pressure to be effective.

Use a Slotted Screwdriver or a Hacksaw Blade

If the bolt is stuck and no other tools seem to fit, you can try modifying the head using a rotary tool like a Dremel or a hacksaw blade. Carefully cut a straight slot across the bolt head, making sure to keep it deep enough for a flathead screwdriver to grip. Once the slot is ready, firmly insert the screwdriver and turn it to remove the bolt. This simple but effective technique works well when precision is needed to loosen a stubborn bolt.

Use a Torque Wrench for a Secure Grip

If you’re dealing with a stubborn bolt, a torque wrench is a great tool to apply the right amount of controlled pressure without damaging nearby components. This method is often used by mechanics and professionals in automotive and machinery repairs. If available, position the wrench over the bolt, ensuring a precise grip, then loosen it steadily. This safer approach helps avoid unnecessary damage while making removal easier.

Secure the Bolt with a Socket Wrench

If an Allen bolt is stuck, a socket wrench can be a strong alternative. Find a socket that fits snugly onto the bolt head for a firm grip. This method allows for controlled removal without damaging the surface. A deep socket is useful for reaching recessed bolts, making the job easier in tight spaces.

Try an Open-Ended or Combination Wrench

If the bolt head is slightly exposed, an open-ended or combination wrench can work as an effective alternative. Ensure the wrench fits tightly around the bolt before turning it counterclockwise. This method grips the bolt externally, allowing controlled movement without damaging it.

Enhance Grip with a Rubber Band

If your Allen wrench is slipping, adding rubber can provide extra traction. A wide rubber band placed over the hex hole of the screw helps create a tighter grip. Push the wrench in so it fits firmly, then try unscrewing the bolt as you normally would. This method increases the chance of getting enough grip to remove the fastener. If a rubber band isn’t available, a disposable rubber glove also works in a pinch to achieve similar results.

Use Friction Drops for a Secure Grip

If your Allen wrench keeps slipping due to a loose fit, using friction drops can be a helpful method. These drops contain fine metal particles that fill gaps inside the bolt socket, creating extra grip. Simply apply a small amount of the solution into the stripped hex hole, then push the wrench in and wiggle it slightly to let the drops catch. This technique works well when other methods slip. If needed, a substitute tool can also be used. You can buy friction drops online or at a local hardware store for easy access.

Try Channel-Lock Pliers for a Firm Grip

If the bolt has a raised head, using channel-lock pliers can be an effective way to get a secure grip. First, clamp the jaws of the pliers firmly around the bolt head to prevent it from slipping. Then, turn counterclockwise to start the removal process. This method works best when other gripping tools are unavailable or if the Allen bolt is stripped. If it feels stuck, try closing the pliers tighter and applying steady force until it starts to loosen up. You can find channel-lock pliers in most tool kits, or you can buy them at a hardware store if you don’t already have a pair.

Use a Hammer to Free a Stuck Bolt

If an Allen bolt is stuck, try gently tapping a screwdriver’s handle with a hammer while it is inserted into the hex hole of the stripped bolt. This method works well when other techniques fail because the shock helps break corrosion bonds and makes the screw easier to get out. Choose a screwdriver with a bit that fits snugly. Start by hitting the bottom lightly, then slowly increase the force until the bolt begins to loosen up. If it still won’t be removed, try another way. Always wear safety glasses to protect from flying pieces of metal, especially when working with thin or delicate materials.

Use a Center Punch for Stubborn Bolts

A center punch with a spring-loaded mechanism and sharp tip can create enough force to turn a stuck bolt counterclockwise when struck repeatedly. This is useful for loosening rusted or frozen bolts. To start, place the pointed end of the punch on a flat part of the screw head, ensuring the sharp end points left. Then, pull up the spring and let go to apply sudden force. It may take a few tries, but the punch will catch and help unscrew the bolt with each hit. If needed, tap the back of the punch’s handle with a hammer for extra power.

Secure an Old Allen Wrench with Epoxy

If a stripped bolt won’t unscrew, an old Allen wrench and two-part epoxy can be a last-resort method that works well. First, apply the 2-part epoxy inside the bolt head and spread it onto the end of the Allen wrench. Then, press it in place and let it set completely for 1–2 days to allow proper drying. Once dry, firmly turn the Allen wrench counterclockwise to remove the screw. This method is useful but permanent, so don’t mind getting rid of the wrench, as you won’t be able to use it again. You can buy epoxy at a local hardware store, but be careful not to get it on the surface around the bolt, or it may get stuck permanently.

Create a Slot for a Flathead Screwdriver

If nothing else works, using an angle grinder is a last resort to remove a stripped Allen screw. Carefully cut a straight slot into the bolt head, making sure to avoid damaging surrounding surfaces. A new slot will allow a flathead screwdriver to unscrew the bolt easily. Since an angle grinder is a power tool with a rotating circular blade, it can cut through metal effortlessly. Start by drawing a line on the top of the bolt to follow, and always put on a pair of safety glasses for protection. Once the grinder has made a shallow cut, just turn the flathead screwdriver counterclockwise to get the screw out. If you don’t have a grinder, try hitting the screwdriver with a chisel to create a similar effect.

Try a Screw Extractor for Stubborn Bolts

If the bolt head is broken or heavily damaged, using screw extractors is one of the best methods to remove it. These tools are designed to handle stubborn screws and bolts. Start by using a drill to make a small hole in the middle of the bolt head. Then, insert the cutting drill bit side of the extractor into the hole and cut a shallow groove. Once that’s done, flip the extractor to the removal bit, put it in the new hole you just made, and set your drill to reverse. This will help you unscrew the bolt as it pulls out. You can buy a screw extractor kit from a local hardware store for around $10–20 USD, and since it’s reusable, it’s worth keeping in your toolbox for future use.

Drill the Screw Out

If an old Allen bolt is stuck, grinding it out with a high-torque drill can be effective. First, choose a drill bit with the right diameter to match the screw’s threads and put it in your drill. Set the bit inside the hex hole, then wear a pair of safety glasses before you start. Apply light downward pressure and use a low, slow speed to carefully drill straight through the screw. Once finished, easily pull the remaining piece left with needle nose pliers to clear the hole.

Use Heat to Free a Stuck Allen Bolt

If you’re struggling to get a stripped allen screw out of metal, applying heat works best to loosen it. First, put on safety glasses for protection, then light a butane or propane torch and hold the tip of the flame over the screw head for about 5–10 seconds, but don’t let it turn red hot. Once heated, insert an allen wrench into the hole and try turning the screw or bolt counterclockwise to fully remove it. However, avoid using this method on delicate or flammable materials, as it may cause damage.

Image Credits

We appreciate the creators and websites that have provided the images used in this article. The following sources have contributed visuals that help illustrate key points:

FAQS

How to unscrew allen bolt without Allen key?

You can remove an Allen screw without an Allen key by using a flat screwdriver with a wide blade that fits securely between the opposing corners of the screw head. To prevent slipping, place a rubber glove over the blade before turning it. This method helps grip the screw better and allows for easy removal.

What can I use if I don’t have an Allen key?

If you don’t have an Allen key, you can use ratchet bits, 1/4″ drivers with hex bits, T-handles, or Y-keys as alternatives. These tools provide a secure grip and make it easier to loosen or tighten the Allen screw efficiently.

How do you unscrew a hex screw that won’t budge?

Apply penetrating oil to the hex screw and let it sit for 10 to 15 minutes so the lubricant can seep into the threads, breaking down rust and grime. Once it has soaked in, use a wrench to gently turn the screw and see if it begins to loosen. If it still won’t budge, try applying gradual force or using a longer handle for extra leverage.

Is there an Allen screwdriver?

Yes, an Allen screwdriver is designed for precise and reliable performance in various maintenance and repair tasks. With an ergonomic handle, it helps reduce hand fatigue during long use, making it ideal for assembling, repairing, and fine-tuning equipment.

What to use if you don’t have a wrench?

If you don’t have a wrench, you can use two large coins as a makeshift tool. Simply place them on opposite sides of the nut, grip them firmly between your index and middle fingers, and twist in the needed direction to loosen the nut. This trick works best with larger coins that provide a secure grip.

How to make a homemade Allen key?

to make a homemade Allen key in an emergency, you can use a hexagonal-barrel pencil and a knife. First, cut off the end of the pencil to create a flat, strong edge. Then, insert it into the bolt head and turn it carefully. This quick DIY method can help in a pinch when you don’t have a proper tool available

What is similar to an Allen key?

A hex key and an Allen key are essentially the same tool, often used interchangeably. Other similar tools include Torx keys, hex wrenches, and ratchet bits with hex heads, all of which serve a similar purpose for loosening or tightening hexagonal fasteners.