If you’ve ever felt tired of endlessly turning a standard wrench or struggled with repeatedly repositioning it to tighten a nut or bolt, a socket wrench is the perfect solution. This introductory guide will help you understand how a ratchet works and why it’s such an efficient tool for house or automotive repairs. Unlike traditional wrenches, a socket wrench allows you to tighten or loosen fasteners much quicker and easier by simply moving the handle back and forth, without needing to lift or reposition the tool. Whether you’re working on your home or tackling repairs on your car, this tool is a perfect addition to your toolbox.

Using a socket wrench set is straightforward once you know the basics. First, choose the correct socket size for the nut or bolt. Attach the socket to the square drive and adjust the ratchet lever to the proper direction—right for tightening and left for loosening. As you push the handle, you’ll hear clicks from the ratchet, indicating it’s working. To tighten, turn the handle clockwise, and to loosen, turn it counterclockwise. The ratcheting mechanism keeps the fastener in place, allowing you to finish your task faster without unnecessary effort. This tool saves time and makes even first-time repairs feel effortless.

How to Use a Socket Wrench: Step-by-Step for Beginners

To use a socket wrench, first, select the appropriate socket size that fits the fastener you need to tighten or loosen. Attach the socket to the wrench’s square drive and ensure it locks in place. If your wrench has a ratchet mechanism, set the direction switch to either tighten or loosen. Place the socket over the fastener, ensuring a firm grip, and turn the handle in the desired direction. The ratcheting feature allows for continuous motion without needing to reposition the wrench. For added torque, use an extension bar or breaker bar. Once the fastener is secured or removed, detach the socket and store the wrench properly.

What Is a Socket Wrench?

A socket wrench is a specific kind of wrench designed to turn fasteners like nuts and bolts. It has a socket on one end of the tool and often includes a ratchet wrench feature for easy tightening or loosening. This handheld piece of equipment uses a ratcheting system that allows pushing or pulling the handle without needing to remove it from the fastener. Typically, the socket is fitted to match the size of the fastener, making it useful for a wide range of tasks. Included in many basic maintenance kits, it works alongside other tools like a valve wrench or strap wrench. Following safety practices and proper care will help extend the lifespan of your tools.

Step-by-Step Guide: How to Use a Socket Wrench

Using a socket wrench is simple once you understand the intuitive steps. Start by selecting the correct socket for your nut or bolt, considering whether the fastener is metric or imperial. Most socket sets include a variety of sizes and variants to ensure you can handle any job. Attach the socket to the wrench handle by sliding the square peg into the hole on the socket’s head, ensuring a snug fit. For tightening, select the clockwise orientation on the ratchet, or switch it to anticlockwise for loosening. As you rotate the handle, the ratchet mechanism allows smooth action without needing to constantly lift the tool. If working in tight spaces, a spanner or extension can help. Always apply torque carefully to avoid stripping the nut or bolt, especially when working on difficult-to-remove fasteners.

Below Are Detailed Step by Step Guide.

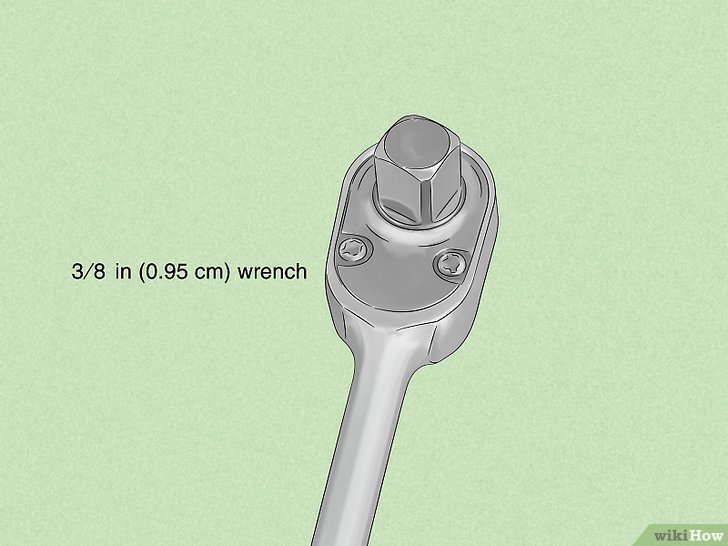

Step 1: Choose the Correct Fastener Size for the Job

Choosing the right wrench depends on the size of the fastener and the task. A 3⁄8 in (0.95 cm) wrench works best for most repairs, fitting a widest range of sockets in standard sizes, making it perfect for common nuts and bolts. For smaller tasks needing precision, like adjusting a vehicle drive belt, a 1⁄4 in (0.64 cm) wrench is ideal. For large fasteners or heavy machinery, a 1⁄2 in (1.3 cm) wrench provides the strength and torque required. The wrench size is determined by the drive, which is the square-shaped knob at the end of the tool that secures the socket. Always ensure the socket fits properly to avoid damage, and be cautious not to overtighten to protect both the wrench and the lug nuts or other fasteners.

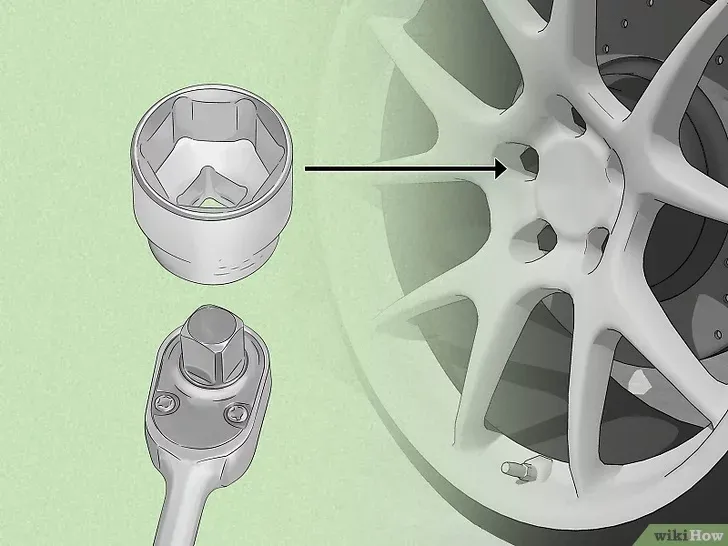

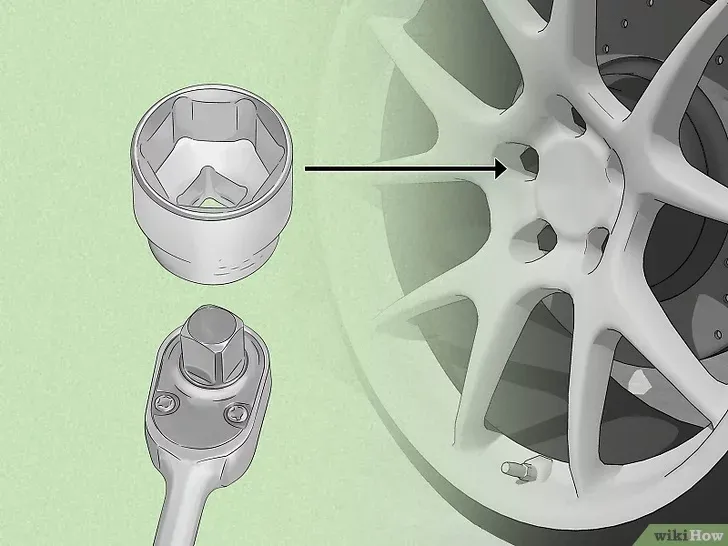

Step 2: Select the Right Socket for Your Nut or Bolt

When working with a nut or bolt, always choose a socket that matches the exactly same size to ensure a snug fitting. The socket should completely cover the fastener and not wiggle, which helps prevent stripping. For deeper or hard-to-reach spots, opt for a deeper socket, while a shallow socket works fine for surface-level tasks. A socket set with both SAE and metric sizes gives you the right options for various jobs. Always lock the appropriate socket in place on an adjustable wrench set or ratchet to handle tasks efficiently, whether using standard, removable sockets, or tackling a wider range of fasteners.

https://www.wikihow.com/

Step 3: Attach the Socket Firmly to the Wrench

To begin, push the socket onto the square drive end of the wrench until it clicks and locks firmly in place. This ensures the tool is ready for use and won’t slip during operation. For difficult-to-reach fasteners, you can attach an extension to the socket wrench for better access to the nut or bolt. It’s advisable to check the wrench set before using it to ensure everything is operating correctly. Hold the tool firmly in place with your hand while turning the ratchet repeatedly left or right, depending on whether you are tightening or loosening.

https://www.wikihow.com/

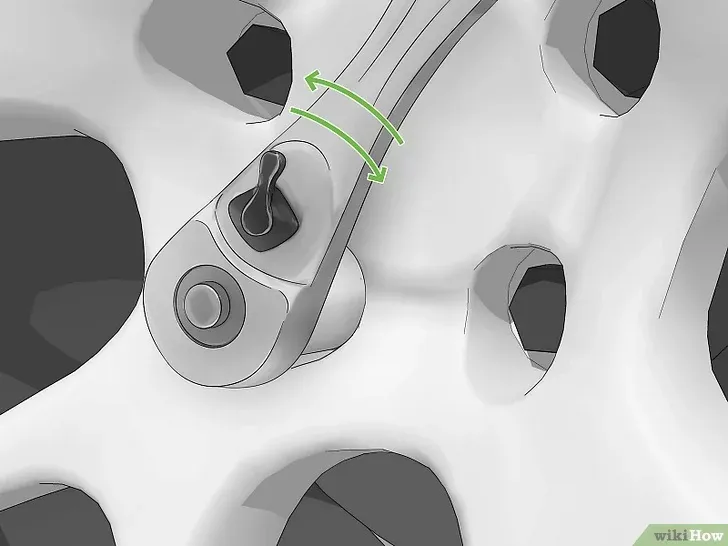

Step 4: Set the Wrench’s Lever to Adjust Turning Direction

To control how your wrench works, simply flip the lever on the back of the tool. This lets you choose whether to tighten or loosen a nut or bolt by changing the direction of the ratcheting mechanism. Turn the knob attached to the drive and test the movement by spinning it clockwise to tighten or counter-clockwise to loosen. Always connect the socket securely to the head of the fastener to ensure a strong fit, and make adjustments with precision. During this crucial phase, hold the tool steady with one hand to avoid slipping.

https://www.wikihow.com/

Step 5: Tighten or Loosen the Fastener by Rotating the Wrench

To tighten or loosen a fastener, begin by securing the socket onto the nut or bolt and ensure a firm grip to prevent the tool from rotating in the wrong direction. Turn the wrench handle clockwise to tighten or counterclockwise to loosen, depending on the task. With the ratcheting mechanism, you can move the handle far and let it slide back to the starting position without lifting, making the process faster and smoother. If you feel resistance, check the direction and reposition if needed to avoid twisting in the wrong direction. Keep going until the nut or bolt is either completely tight or ready to remove.

Step 6: Safely Remove the Socket After Use

To remove the socket from the wrench, locate the button on the back of the tool. This button acts as a quick-release mechanism that releases the catch holding the socket in place. Simply press the large button down firmly and gently pull the socket straight down to detach it. Once removed, make sure to put the socket in a container so it doesn’t get lost or damaged. This process is simple and requires minimal strength, thanks to the tool’s design. Avoid rotating the handle unnecessarily while working on a tight or loose fastener, as this ensures the quick-release remains efficient for removing or replacing parts

3. Pro Tips for Effective Socket Wrench Use

When working with a socket wrench, it’s crucial to choose the correct size for the nut or bolt to prevent damage and ensure a secure fit. Always inspect your set before starting to catch any wear or cracks that could affect performance. When using the ratchet mechanism, make sure the socket is fully seated on the fastener to avoid slipping. Apply consistent pressure while you turn in small increments for precise control and to prevent over-tightening. In tight spaces, use extensions and other accessories to reach difficult areas and apply extra leverage when needed. To avoid strain, regularly maintain your tools and efficiently handle each task by following these best practices.

What are Sockets & Socket Sets?

Sockets are specialized tools designed to work with wrenches for tightening or loosening nuts and bolts. They can be bought individually or as part of socket sets, which are often bundled in a kit for various jobs. Unlike a regular spanner, socket wrenches have an inbuilt ratcheting mechanism that allows the user to apply torque in one direction while the tool resets in the other, making the process much quicker and reducing strain on your hands and wrists. Socket sets come in an assortment of sizes, often including both imperial and metric variants, and are ideal for tight spaces like under fixtures, radiators, or inside cupboards. They feature differently sized drives that can be attached to the wrench head and easily swapped to handle fasteners of various shapes. This design ensures a more convenient and efficient way to tackle fastening tasks.

Different Types of Socket Wrenches

There are numerous types of socket wrenches available, each offering varying features to suit different tasks. A basic tool includes a solid handled wrench with a built-in ratchet mechanism that allows you to apply torque and easily switch direction between clockwise and anticlockwise. Some types come with adjustable features, quick-release adapters, or are part of multi-part kits for added functionality. While basic sets are affordable, higher-quality tools from reputable brands often provide extra benefits and are widely sold separately or as part of premium kits. For buyers, choosing the right type depends on the cost, quality, and specific needs of the task.

Some mechanical wrenches also include advanced ratcheting mechanisms, making them ideal for jobs requiring precision in tight spaces. Adjustable wrenches are versatile, as they allow you to work on a variety of bolt sizes without needing multiple tools. For professionals, investing in premium brands with durable components ensures longevity and efficiency. Additionally, quick-release sockets and adapters simplify the process of swapping between sizes, saving time during work. Whether you’re a DIY enthusiast or a professional, selecting a socket wrench with the right features ensures you’re equipped for any task

Drive Shape

Socket wrenches come in various shapes and drives to handle a wide variety of nut and bolt configurations. Common options include hex sockets, double hex, and square wrenches, each suited for specific tasks. A hex drive is ideal for most everyday jobs, while a square drive is helpful when you encounter unique fastener types. Owning an assorted set ensures you’re ready to tackle both standard and recessed fasteners. To enhance functionality, consider purchasing extenders and other accessories separately, so your tool is equipped for more complex tasks. A complete set is the best investment for tackling a wide variety of challenges.

4. Common Mistakes to Avoid

Main common mistakes we face is that we don’t use accurate socket wrench size which can cause us troubles, here are socket wrench sizes below.

Socket Wrench Sizes

A socket wrench comes in a wide range of sizes, styles, and configurations, making it essential to choose the best tool for your needs. This often involves considering factors like the types of spaces you’re working in, whether they’re tight or awkward to access, and the nuts or bolts you need to handle. Many socket sets feature an assorted collection of differently shaped tools, including mini, half-inch, or deep options for long or recessed fasteners. Adding accessories like extensions or extra pieces can make a big difference in functionality. Popular searches often include ratchet spanners, online bundles, and kits designed for specific turning tasks.

Socket Drive Sizes

Understanding socket drive sizes can seem confusing, but with a little practice, it becomes easy. Drive sizes refer to the distance across the wrench head that attaches to the socket, and common options include ¼”, ⅜”, ½”, and ¾”. These sizes are often marked on the ratchet or socket, making it simple to match the right tool with the nut or bolt you’re working on. For metric and imperial measurements, small fastener sizes like 3 mm to 22mm fit well with ¼-inch drives, while large bolts, ranging from 19mm to 50mm, typically need a half-inch drive or larger. Having a set of assorted kits ensures you’re always prepared to handle a variety of fastener sizes, helping you achieve the required torque with ease. Always test-fit and assess beforehand to avoid trial-and-error.

5. Socket Wrench Maintenance Tips

Tool Maintenance Tips and Techniques

socket wrench, socket set, high-quality, various projects, simpler, socket sizes, much force, handle, jaw, harming fastener, proper size, excessively large, loose, strip, destroy, slide, dangerous extensions, socket wrench set, different tasks, shorter, longer bar, accommodate extensions, different extension sizes, remote, difficult-to-reach areas, automotive components sockets, separated by size, put back, save time, energy, resources handy tool safety guide, every time.

6. Frequently Asked Questions (Address user queries directly for SEO)

How to use a socket wrench step by step?

Position the wrench to the left for tightening the fastener or to the right for loosening it. Securely place the socket over the nut, then turn the handle clockwise to tighten or counterclockwise to loosen. Ensure the socket stays firmly on the nut or bolt while moving the wrench handle back to its starting position for repeated turns.

How do you use a wrench step by step?

Position the open jaw over the nut and secure it firmly. Adjust the screw mechanism to clamp tightly around the nut. Rotate the wrench in a clockwise direction to tighten, or counter-clockwise to loosen. Continue turning until the nut is snugly tightened or loose enough for easy removal.

Should the socket wrench turn clockwise or counterclockwise?

To loosen a nut or bolt, rotate the socket handle counterclockwise. To tighten, turn it clockwise. If the socket isn’t moving in the right direction, simply flip the lever on the back of the ratchet to change the rotation.

How to take the socket off the wrench?

I’d carefully insert a flathead screwdriver into the gap between the edge of the socket and the bolt. With a slight twist of the screwdriver, I’d apply pressure to ease the socket off the bolt while gently moving the wrench or socket back and forth for better leverage.

What is the use of a socket wrench?

Socket wrenches are essential hand tools designed for the efficient tightening and loosening of various fasteners, particularly nuts and bolts. Unlike traditional spanners and wrenches, socket wrenches feature a ratcheting mechanism that enables users to apply torque with greater ease. This innovative design reduces strain and fatigue, making it a preferred choice for both professionals and DIY enthusiasts.

How do you unscrew something with a wrench?

To tighten a nut or bolt, turn the wrench clockwise. Conversely, to loosen it, turn the wrench counterclockwise—remember the phrase “Righty tighty, lefty loosey.” If you encounter a situation where the wrench cannot complete a full rotation, simply reset the wrench jaws after each turn to continue adjusting the fastener effectively.

Why do you need a socket wrench?

A ratchet and socket set, often referred to as a socket wrench, is a versatile tool designed to simplify the process of turning nuts and bolts. Unlike traditional wrenches that require you to reposition the tool after each turn, a ratchet and socket combination allows for continuous rotation without needing to lift the tool off the fastener. This feature is particularly beneficial in tight spaces where full circular movement is restricted, making it easier to work efficiently and effectively.

How to Use a Ratchet Socket Wrench

Using a ratchet socket wrench is straightforward if you follow this step-by-step guide. First, choose the right socket that fits the size of the nut or bolt you’re working on; sockets come in various sizes, so ensure it’s correct. Attach the socket by pushing it onto the square drive of the ratchet until it clicks into place. Set the direction of the ratchet using the switch, which allows you to change between clockwise for tightening or counterclockwise for loosening. Position the socket on the fastener, and turn the ratchet handle to pull in the desired direction; the ratcheting mechanism will let you turn back without losing position on the fastener. For deeper or hard-to-reach fasteners, use extensions if needed. Be cautious to avoid over-tightening, which can strip or break the fastener. Always follow safety precautions, like wearing glasses to protect your eyes from debris, and use the right size to avoid stripping the fastener.